Automatic negative air pressure three-station plastic forming machine HD-SP-850L

Key words:

Blister machine series

Classification:

Product Details

Full-automatic Negative Air Pressure Three-station Blister Forming Machine HD-SP-850L

adopts the infrared heating system of upper and lower electric furnaces to effectively heat the material. The temperature is controlled so that the material is not completely cured and sagging. When the sheet is moved to the forming station by the pull tab motor, the servo pressure system is started, and the material is vacuum formed by negative air pressure through the upper and lower fitting of the mold. Cutting and stacking are completed simultaneously. That is, the formed product is driven by the motor to the separation station, the separation is completed, sent out by the conveyor belt, and the waste is recycled, thus recycling the program and high-speed production.

Advantages: high-speed negative air pressure blister production, high efficiency, uniform thickness, fully realize the assembly line production process.

Process Flow:

Uncoiling and Feeding-Electric Furnace Preheating-Double-sided Heating and Baking-Negative Air Pressure Vacuum Forming-Servo Cutting Machine (Slitting)-Servo Sending (Full Break/Half Break)-X, Y, Z Triaxial Servo Stacking-Scrap Roll

Equipment Composition

1, Body Structure: 100*100mm Square Tube Welding, make the frame more solid, pressure to meet the design requirements. And according to the need in the key parts of the bolt connection, easy to install, remove and repair replacement.

2. Molding mechanism: servo-driven molding is adopted to design the integral four guide posts, and is matched with cold-plated optical axis, oil-containing shaft sleeve and coaxial design of the upper and lower parts of the mold. So as to smooth the lifting action, to achieve the upper and lower die high-precision fit requirements, the upper and lower templates using thick steel plate, and grinding smooth, die size design and mold size.

3, feeding system: a large pneumatic feeding rack is adopted, which can feed 200kg/roll at a time, and an expansion wheel is adopted to lock the material. the motor has the function of forward and reverse operation, which is convenient to rewind and unwind the pieces.

4. Heating part: ceramic infrared heating bricks with double length up and down double electric furnaces are used for uniform heating, and the temperature control adopts pressure regulating digital control system, which makes the temperature of the heating area flexible and adjustable, and has more intuitive functions. Realize multi-point temperature adjustment, realize the combination of macro-temperature control and micro-temperature control, that is, can reach the temperature of the unified heating furnace, and then make a single supplementary temperature fine adjustment for special circumstances to shorten the heating time and improve the production speed.

5, electrical control system: the design adopts PLC program control, large touch screen as man-machine interface, all Chinese input is intuitive and clear, and the operation is simple. The equipment is equipped with safety shutdown system and emergency stop switch to provide safety guarantee for production.

6, cutting system: servo drive bidirectional cutting design, high precision cutting products. The cutting mechanism is equipped with a positioning slicing device to separate and cut the product, which is sent out by the manipulator and then moved to the conveyor belt by the manipulator suction cup stack.

7. Vacuum-assisted molding system: The rotary vane vacuum pump is used to perform vacuum blister molding on the molding material at the moment of compression molding, so that the material is more consistent with the mold and meets the quality requirements of the product.

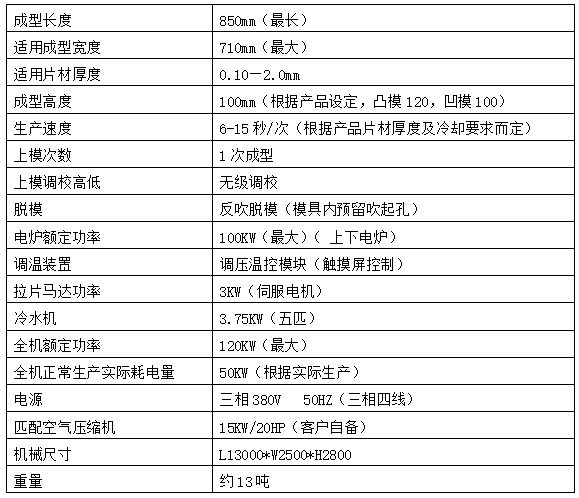

Specification Configuration

1, Standard Specification

Related Products

Product inquiry

online message

Bottom link

Address: Factory Building ,No. 9, 3293 Hongmei South Road, Minhang District, Shanghai

Zip Code: 201108

Tel: 021-66613330 021-66613320

Fax: 021-56558970

Mobile Phone: 13901833321 13585855550

Mailbox: hongdu@vip.sina.com