Automatic Blister Forming Machine HD-SPV

Key words:

Blister machine series

Classification:

Product Details

Full-automatic blister forming machine HD-SPV

uses side-shift electric furnace infrared heating system to effectively heat the plastic material. The temperature is controlled so that the blister material is not completely cured and sagging. When the sheet is moved to the forming station through the pull-tab motor, the pneumatic system is started, supplemented by the upper booster die, and the blister material is blister formed through the fit between the die and the sheet. After forming, the product is moved to the feeding platform, at this time, the conveying system works so that the second operation sheet does not move back and offset, and the cutting device automatically cuts the material according to the required length, thus circulating the program and producing at high speed.

Advantages: fast heating, uniform heating, accurate pull, high production efficiency, low scrap rate, suitable for blister products with certain difficulties.

equipment constitutes

1, fuselage structure: No. 8 flat welding is adopted to make the frame stronger and the pressure resistance meets the design requirements. And according to the need in the key parts of the bolt connection, easy to install, remove and repair replacement.

2. Molding mechanism: the upper and lower dies are designed with four guide pillars and matched with cold plating optical axis. So as to smooth the lifting action, to achieve the lower mold and sheet high-precision matching requirements, design tonnage rising extrusion force to meet the requirements of product molding, mold table size design and mold size consistent, mold plate adopts all aluminum cold water circulation cooling mold plate.

3, Feeding System: Large feeding rack is adopted, which can feed 30-300kg/roll at a time, and double-shaft alternating locking technology is adopted. The motor has positive and negative operation functions, which is convenient for collecting and releasing pieces, automatic feeding rack and lifting function.

4. Heating part: ceramic infrared heating brick is used for uniform heating, the temperature of the heat insulation plate is reflected by mirror, and the temperature control adopts digital voltage regulation compensation silicon controlled temperature control system, which makes the temperature of the heating area flexible and adjustable, and has more power saving function, thus shortening the heating time and improving the production speed.

5, electrical control system: the design adopts PLC program control, large touch screen as man-machine interface, all Chinese input is intuitive and clear, and the operation is simple. The equipment is equipped with emergency stop switch to provide safety guarantee for production.

6. Cutting system: adopts active double guide rail horizontal cutting design to cut products with high precision.

7. Safety protection: A fully enclosed molding station is adopted to open and stop the operation device, and a plexiglass protective cover is installed at the blanking and breaking position. The safety design can effectively prevent operators from misoperating and entering dangerous institutions by mistake.

8, vacuum system: high-power industrial rotary vane vacuum pump is adopted, which is adsorbed by large vacuum at the moment of plastic suction molding, so that the material and mold are matched and shaped, and the size of fast and slow vacuum can be selected according to needs to meet the requirements of product technology.

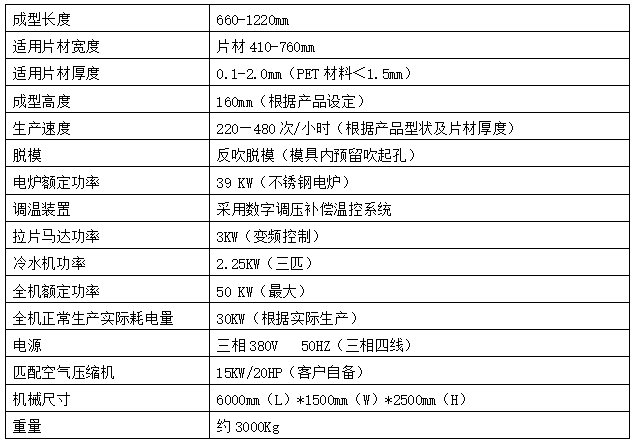

Specification Configuration

Related Products

Product inquiry

online message

Bottom link

Address: Factory Building ,No. 9, 3293 Hongmei South Road, Minhang District, Shanghai

Zip Code: 201108

Tel: 021-66613330 021-66613320

Fax: 021-56558970

Mobile Phone: 13901833321 13585855550

Mailbox: hongdu@vip.sina.com